GVSU medical group collaborates to improve spinal surgery training

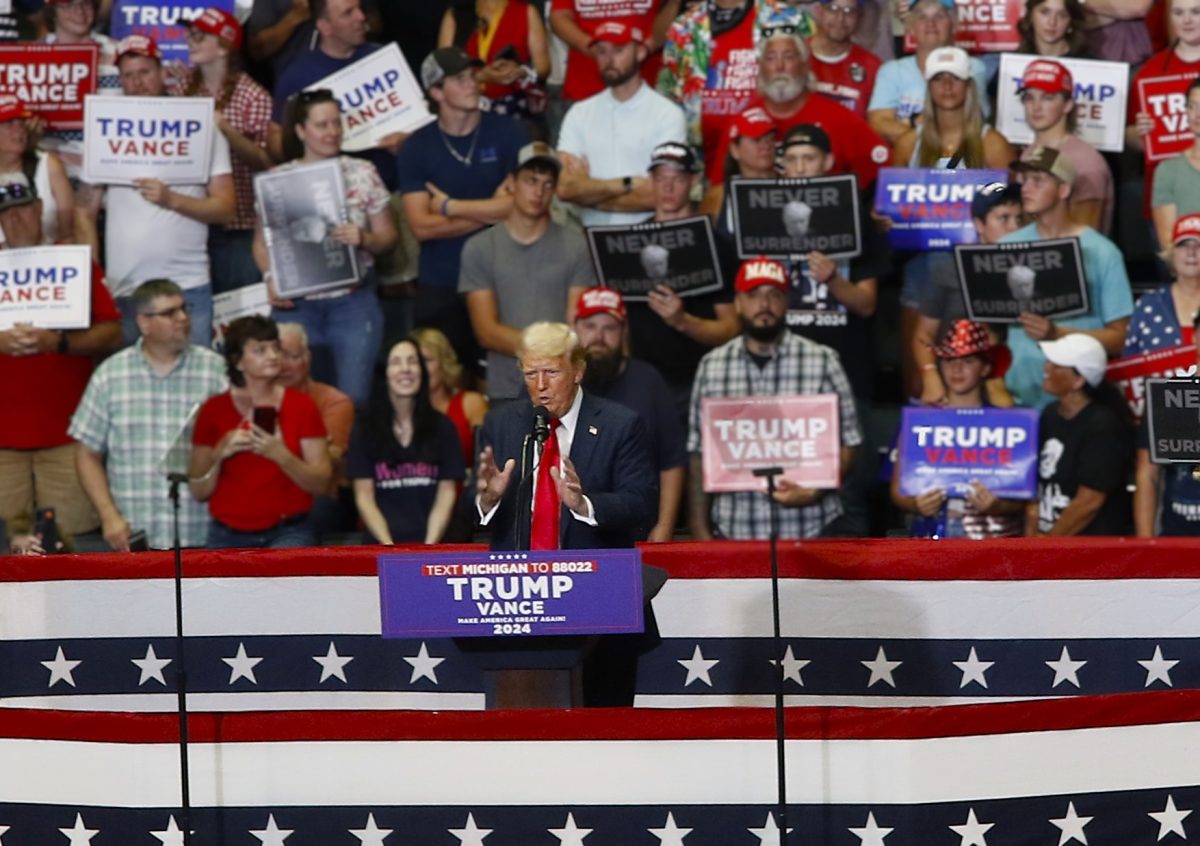

GVL / Courtesy – Amanda Pitts From left, Noah Keefer, Maruf Hossain, Jim TenBrink, Brent Nowak, Jon Vinkso and John Doneth.

Feb 1, 2018

A group of Grand Valley State University students recently worked with Encoris, a medical device manufacturer based in Holland, Michigan, to develop a spinal training device designed to lower costs of training and increase hands-on learning for students in the medical profession. GVSU’s applied Medical Device Institute (aMDI) worked in conjunction with Encoris CEO Jim TenBrink to create a system of cameras for the S2T Surgical SmartTrainer, reducing the need for cadavers and harmful X-rays during training.

Brent Nowak, the executive director of the aMDI, explained the potential market for the SmartTrainer and the opportunity it has to become an asset to medical programs across the country.

“What they typically do is they’ll fly in tens or hundreds of doctors to a huge surgical suite where there’s maybe four or five surgical tables set up,” Nowak said. “They’ll have cadavers there, and they’ll demonstrate the surgery. As you might expect, it’s very costly to do that, so wouldn’t it be better if we used our device and we were able to mimic the X-rays that the surgeons have?

“They came up with an idea that they could use their model to train surgeons on these critical procedures. They conceived a human torso where there’s a shell around it and you have a spine inside that shell. They created a foam material that gives you a more textured feel, so you can generally base surgery on this spine and you can train surgeons on it.”

Nowak emphasized the engineering prowess his group displayed in developing an internal camera system for the SmartTrainer.

“We were able to put four cameras inside the shell, which represents the torso, and they can move those cameras in the same fashion as the big C-arm on the outside during surgery,” he said. “What we did is we shrunk it down and put the camera inside the body.”

TenBrink, who invented the SmartTrainer and is also a GVSU alumnus, said the camera system is a crucial part of the device.

“With the high-def cameras, they also built a rail system that keeps those cameras strategically aligned along the spine,” he said.

TenBrink acknowledged that cadavers will always play a role in the medical profession but said his invention both reduces training costs and mitigates students’ exposure to harmful radiation sources.

“The gold standard of training are cadavers,” TenBrink said. “However, they have a lot of limitations. They have a limited supply, they have limited pathologies, so the diseases the surgeons want to correct aren’t there, and they require X-rays. If you think about X-rays, you’re limited to a hospital facility. It’s very expensive, and it’s dangerous because you have radiation. With my invention I’m looking to solve all three of those problems.”

TenBrink believes the SmartTrainer eliminates the need for students to be exposed to radiation through X-rays.

“Surgery right now, specifically spinal surgery, is minimally invasive, meaning it requires a tremendous amount of X-rays, and medical students are being subjected to tremendous amounts of X-rays right out of the gate,” he said. “So, why during training do you need to subject students to dangerous radiation? This is one tool that can provide safety and minimize exposure to radiation.”

Both TenBrink and Nowak spoke highly of the device’s prospects, as unlike a cadaver, the SmartTrainer can be used countless times, reducing the complications commonly associated with training for spinal procedures.

“The idea is that you would use this spine to train two or three doctors, then take it out and put another spine in,” Nowak said. “You can keep reusing this rather than having to keep doing surgeries on cadavers.”

“Let’s say a medical device company has six implants that they’re launching into the market,” TenBrink said. “That sales representative can take a SmartTrainer along with six spine inserts and do training on the spot with any number of surgeons. You cannot do that with a cadaver.”

Another feature of the SmartTrainer is its ability to simulate various conditions, such as multiple sclerosis. Since the training device is prefabricated and parts are interchangeable, different bone model components can be inserted to mimic a cadaver with a particular spinal condition.

“When you get cadavers, they won’t all have the diseases you want to practice on,” Nowak said. “They can create all these different disease states or pathologies, and now people can actually practice on these different disease states rather than practice on an ideal spine.”

The possible ailments for the SmartTrainer to simulate are practically endless.

“We can manufacture as a company an unlimited supply of trainers and bone model inserts which are pathology-specific,” TenBrink said.

TenBrink said opportunities for the SmartTrainer extend outside the country, as well, since developing nations and regions that oppose operating on cadavers would ultimately benefit from the spinal training device.

“In third-world countries where they don’t have good access to surgical training, given the portability of the Smart Trainer and how they have access, they can do this literally in an African hut,” TenBrink said.

Both TenBrink and Nowak had high praise for the device and the work involved in developing it, and both emphasized the importance of the aMDI group in engineering the internal cameras for the SmartTrainer. They hope the device will create a safer, more fulfilling training experience for medical students entering the orthopedic field.